Why my resin is still sticky?

- Inaccurate Measurement (Resin and Hardener): Precision is crucial in resin projects. Even slight deviations from the recommended ratio can lead to stickiness or incomplete curing.

- Undermixing Resin and Hardener:

Inadequate mixing may result in uneven distribution of components, leading to areas with incomplete curing and stickiness. - Insufficient Warming of Resin and Hardener:

Some resin formulations require warming to reach their optimal viscosity for mixing. Cold temperatures can hinder the chemical reaction, causing stickiness. - Not Enough Resin and Hardener for the Chemical Reaction:

Insufficient amounts of resin and hardener may prevent the chemical reaction from occurring properly, leading to a tacky surface. - Using Components from Different Kits:

Different resin formulations may have varied curing times and properties. Mixing components from different kits can result in an improper chemical reaction and sticky resin. - Water Contamination:

Moisture from the environment or tools can negatively impact the resin curing process. Always ensure that the working area, tools, and materials are dry. - Insufficient Curing Time:

Some resins require more time to cure fully. Patience is key, and allowing the resin adequate time to harden according to the manufacturer’s guidelines is essential.

Bonus Tip: Every resin is unique! Check the manufacturer’s guide for your specific one. By mastering proper mixing and keeping things dry and warm, you’ll be a resin pro in no time, with smooth, cured projects to show for it!

Crystal Resin

Crystal Resin Diamond Resin

Diamond Resin Geo-Resin

Geo-Resin UV Resin

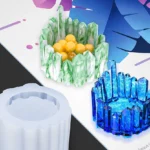

UV Resin Resin & Concrete Molds

Resin & Concrete Molds Candle & Soap Molds

Candle & Soap Molds Jesmo-Resin & Gypsum Molds

Jesmo-Resin & Gypsum Molds Christmas Molds

Christmas Molds EID COLLECTION

EID COLLECTION Hand Made Molds

Hand Made Molds

Pearlscent Mica

Pearlscent Mica Chameleon Powders

Chameleon Powders Candle Dyes

Candle Dyes Candle Chips

Candle Chips Alcohol Inks

Alcohol Inks Candle Making Tools

Candle Making Tools Coconut Natural Wax

Coconut Natural Wax Sand Ice Wax

Sand Ice Wax