Not all types of epoxies are used for every project !!

Companies that claim their epoxy works for every project might be simplifying the information for marketing purposes or to make the purchasing decision easier for customers. However, salesman should guide customers based on their specific use case. The right guidance can lead to better outcomes for artists and creators, for instance ensuring they get a product that suits their particular project requirements.

As for IBRAYAs we work on our R&D to assure highly restricted quality measurements for each need separately.

Factors that might influence the choice of epoxy resin include:

1. Project Size and Depth: For shallow coatings or thicknesses up to 2cm per pour IBRAYAs crystal resin is perfect, while others are formulated for deep pours such as IBRAYAs diamond resin.

2. Curing Time: Depending on the project, it is preferable to have faster or slower curing time.

3. Viscosity: The thickness of the resin affects its flow and self-leveling properties. Consequently using low-viscosity resins is crucial for coatings, however high viscosity resins may be better for three-dimensional projects.

4. Temperature Resistance: Basically projects exposed to heat or sunlight may require a resin with higher temperature resistance.

5. UV Stability: Since IBRAYAs resins are UV-resistant which prevent yellowing and maintain clarity over time.

6. Clarity and Color Stability: Clear and color-stable resins are crucial for projects where aesthetics are a priority.

7. Safety Considerations: IBRAYAs crystal, Diamond & Geo resins are low-VOC (volatile organic compound) resins for safer indoor use, in other words we take care of safety regulations.

Crystal Resin

Crystal Resin Diamond Resin

Diamond Resin Geo-Resin

Geo-Resin UV Resin

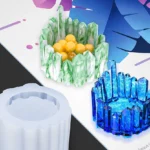

UV Resin Resin & Concrete Molds

Resin & Concrete Molds Candle & Soap Molds

Candle & Soap Molds Jesmo-Resin & Gypsum Molds

Jesmo-Resin & Gypsum Molds Christmas Molds

Christmas Molds EID COLLECTION

EID COLLECTION Hand Made Molds

Hand Made Molds

Pearlscent Mica

Pearlscent Mica Chameleon Powders

Chameleon Powders Candle Dyes

Candle Dyes Candle Chips

Candle Chips Alcohol Inks

Alcohol Inks Candle Making Tools

Candle Making Tools Coconut Natural Wax

Coconut Natural Wax Sand Ice Wax

Sand Ice Wax